Can you Benefit from a Warehouse Execution System?

For warehouse and distribution center owners and operators, achieving faster shipments, lower operating costs, and higher customer satisfaction is always the North Star. But execution on the warehouse floor has historically relied on experienced managers and supervisors doing the best they can with less-than-perfect information, making decisions based mostly on past experience and gut instinct.

But now, technology advancements have made automated decision intelligence accessible to even the most modest warehouse operations.

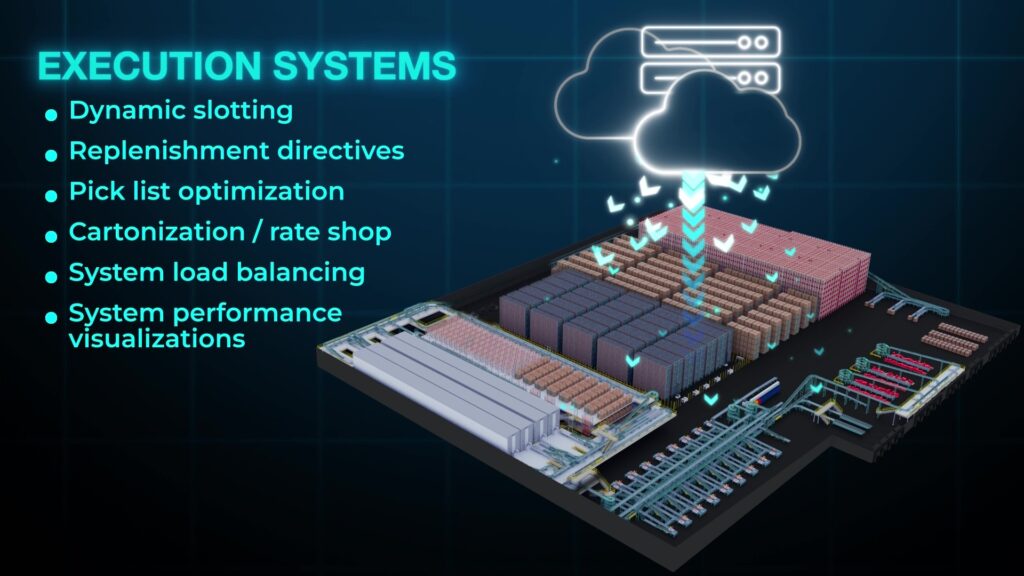

Notice we didn’t say artificial intelligence. There’s nothing artificial about it. We’re talking about Warehouse Execution Systems – or WES.

WES Who?!

There’s a lot of ambiguity about what a WES really is. Unfortunately, the industry hasn’t clearly defined it yet. We’ve seen a number of Warehouse Management System (WMS) providers integrate some execution functionality into their software and rebrand their offering as a WES. Or similarly, a number of robotics providers have coupled some operator interfaces with their robot control systems and started calling that a WES. In both cases what’s touted as a WES is usually much too narrow in its focus.

At its core, a great WES orchestrates operations by balancing demand and capacity across all warehouse processes – from receiving and put-away to picking, packing, and shipping. A great WES ensures that every part of the fulfillment process stays synchronized, preventing bottlenecks that slow down order fulfillment.

Rather than a one-size-fits-few solution that’s too narrowly focused on a segment of your warehouse, your WES should be specifically tailored to fit your whole operation’s unique needs.

Key Components of a Great WES

INBOUND EXECUTION

Inbound execution is usually simpler from a software perspective, but it is generally harder to manage the physical flow due to unpredictable shipment arrivals. And unlike the outbound order backlog, which resides neatly tucked inside a database, the inbound backlog is a pile of “stuff” that needs to be handled before it can even be organized.

An effective WES helps by:

- Triggering Value-Added Services (VAS) – Such as labeling, inspection, or the capture of dimensions and characteristics to prepare each item for further downstream processing

- Providing Slotting Directives – To optimize storage utilization and picking efficiency

- Prioritizing Restocks in Real Time – To ensure high-demand items are always available for picking activities and that no order has to wait for replenishment before fulfillment can begin

- Enabling Cross Docking – To bypass the put-away and picking processes for items being received (or restocked) and also have outbound demand

INVENTORY MANAGEMENT AND OPTIMIZATION

If a DC employs a slotting strategy with multiple forward-pick locations for a SKU, the WES also needs to decide which of those locations is best to pull inventory from when fulfilling orders. That logic may be based on:

- Goods to Person Slotting Strategy – Focus on optimizing location utilization and tote presentation speed

- Random Slotting Strategy – Focus on minimizing pick path distances and over-concentration of picks in a small area

- Bullseye Slotting Strategy – Balance pick path efficiency with replenishment frequency

- Empty Location Cleanup – Favor picks from nearly empty locations to improve space utilization and availability

And while cycle counting may not be a driving force behind your WES, it fits very neatly within the system. For example:

- Zero-count confirmations are an easy and efficient way to help maintain accurate inventory within the picking process

- Scheduled cycle counts can often be conducted in conjunction with location replenishment activities

OUTBOUND EXECUTION

The essence of outbound execution is determining when to release orders to the floor based on demand and available capacity. The idea is to continuously assess the status of each subsystem (i.e. picking, packing, and shipping) and ensure steady work distribution without overwhelming any single process or zone.

Picking

The WES must manage how orders are released to each picking area. Each zone must have clearly defined targets and tolerances to enable workload balancing between the relevant pick areas:

- Automated Goods-to-Person Stations – High-speed and high-volume, but ultra-sensitive to upstream delays

- Conventional Pick Module Zones – Very reliant on traffic management at conveyor diverts and merges to maintain flow

- Roaming Pick Areas – Requires smart batching to minimize operator travel time

Packing

Additionally, the WES needs to orchestrate order release to balance the packing processes, taking into account:

- Bags vs. boxes – Some items may ship more efficiently in polybags, while others require cartons. Since they’re typically different packing stations or areas, the distribution of orders between the two is critical to flow

- Oversized and non-conveyable items – Special packing considerations for irregularly shaped or heavy products often require a different pack station design separate from the main areas handling bags and/or boxes

- Order consolidation – Ensuring items from each of the distinct picking processes come together at the right time and are packed in the same container or pallet is critical to minimizing freight cost and meeting service levels

- Value-Added Services (VAS) – Special labeling, inserts, or kitting may be required at the packing stage

Freight and Packaging

Many DC operators find themselves focused intently on getting orders out the door as fast as possible to meet demand. Unfortunately, this urgency often leads to costly mistakes:

- Suboptimal shipping decisions – Missed opportunities to optimize outbound freight often accounts for 15-20% extra freight cost

- Order errors – Results in late order fulfillment, customer service intervention, and expedited shipments

Consider this:

For every $1 spent on warehouse labor, about $2 is spent on outbound freight. This means that the greatest cost-saving opportunities often lie in optimizing freight and packaging, not just labor.

Optimizing freight and packaging processes also has secondary benefits which can substantially increase the inventory storage capacity of a DC

- Item Characteristics – Capturing length, width, height, weight, nesting potential, and fragility of each item allows systems to optimize both storage and packing

- Cartonization Logic – Using item dimensions and characteristics to determine the most cost-effective packing method for each order as well as the best storage location size (see slotting strategies above)

Choosing the Right Warehouse Execution System

Not all WES solutions are created equally. Before selecting a system, ask yourself:

✔ Does it include all the functionality your operation needs?

✔ Can it be easily configured and reconfigured as your business evolves?

✔ Does it holistically minimize your costs (space, labor, and freight)?

Remember: There is no such thing as a WES; there is only your WES. The right system should align with your operational needs, ensuring efficiency, cost-effectiveness, and scalability as your business grows.

At Siggins, we provide SOLUTIONS, SERVICES and PRODUCTS for your distribution and material handling success story.

Contact us today for a consultation or site survey

Get A Site Survey© 2025 Siggins, All Rights Reserved