Robotic Storage, Retrieval and Pick Systems

Storage and retrieval are two of the most critical tasks of a distribution operation, accounting for the majority of labor and operational costs. Besides improving inventory management and increasing production speeds, robotic storage and retrieval systems increase picking accuracy, a vital component for ensuring customer satisfaction. Warehouses that utilize these advanced systems enhance their operations by minimizing the manual labor associated with storing, picking, assembly and replenishment.

At Siggins, we offer a comprehensive range of robotic storage and retrieval systems for warehouses, distribution facilities and order fulfillment centers, including products from OPEX®, one of the world's leaders in automated material handling solutions. Our highly experienced engineering team can help analyze your existing processes to determine the perfect system for optimizing your operation and speeding up your return on investment. Besides offering off-the-shelf systems from recognized brands, we can also custom-engineer a robotic storage and retrieval solution specific to your application.

Table of Contents

- Applications and Types of Robotic Pick Modules and Systems

- OPEX Perfect Picking Systems

- How the OPEX Perfect Pick HD Module Works

- Benefits of Robotic Storage and Retrieval Systems

- Advantages of Choosing Siggins

- Contact the Experts at Siggins Today

Applications and Types of Robotic Pick Modules and Systems

Automated and robotic storage and retrieval systems come in many shapes and forms. Smaller operations specializing in order fulfillment often benefit from lower-scale automated solutions, while a more comprehensive system might work better for a larger facility. Siggins has experience designing and installing all types of automated material handling solutions, and we can do the same for you regardless of your company's size or the types of products you distribute.

Some examples of the types of systems we feature include:

- Goods-to-person picking: Goods-to-person systems — also called automatic storage and retrieval systems (AS/RS) — often consist of a primary load storage area equipped with an internal crane or shuttle system that delivers products to a workstation for operator packing. These systems eliminate time-consuming walking around a facility by workers while minimizing the inaccuracies often associated with manual picking. Goods-to-person systems can integrate with a warehouse execution system (WES), a warehouse control system (WCS) or a warehouse management system (WMS) to coordinate processes and control inventory management.

- Goods-to-robot picking: Instead of using shuttles and cranes to retrieve bins or boxes containing products like a goods-to-person system, a goods-to-robot solution involves robots picking products directly from a tote or shelf on the floor. These systems use artificial intelligence (AI) vision technology to power the robot's arms and accurately pick items without interfering with other objects. Goods-to-robot solutions can easily integrate with a WES system and perform other warehouse functions like storage and fulfillment.

- Autonomous mobile robots: Autonomous mobile robots (AMRs) can operate individually or as part of a goods-to-robot system to retrieve and deliver items to employees for secondary processing. AMRs are entirely customizable and capable of handling an extensive range of products. These robots can integrate with your WES to safely navigate your facility and perform various tasks other than picking, like sorting and packing.

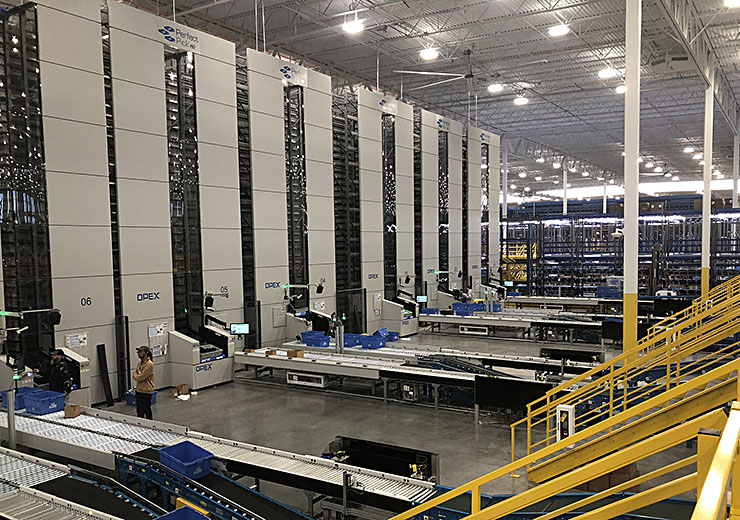

OPEX Perfect Picking Systems

Perfect Pick® from OPEX is an AS/RS system ideal for goods-to-person order picking. Advanced iBOT™ technology empowers Perfect Pick to deliver a secure, energy-efficient solution that offers significant cost savings over manual picking operations. The system is a stand-alone solution consisting of racks and totes inside the main aisleway.

Perfect Pick HD provides increased storage by offering double the capacity of the original Perfect Pick system. Both systems can simultaneously replenish or restock items during the picking process.

Perfect Pick systems can:

- Store and pick trays and totes.

- Access vertical and horizontal storage locations inside the aisles.

- Eliminate the need for warehouse elevators, lifts or vertical conveyors.

- Combine with WES, WCS and WMS systems to control warehouse functions.

How the OPEX Perfect Pick HD Module Works

The Perfect Pick system consists of three primary components — the iBOTs that store and retrieve the products, totes that hold the products and a workstation where employees perform fulfillment or packaging. For storage, workers place items in the appropriate tote at their workstations. The iBOT then transports the product to the designated rack in the system's aisleway.

For retrieval, the iBOT collects the tote and delivers it to the operator's workstation, where the worker picks the product and places it into a box for shipping. The iBOTs move quietly along the conveyor system through the zero-height transfers. Once the operator fulfills the order, the system transfers the packed carton to the final shipping area and indexes another order to the workstation.

Light-directed picking makes this system exceptionally precise. Workers follow visual and text prompts on a workstation screen that guides the entire process. When the iBOT delivers the tote to the operator's workstation, it tilts to prevent strain and provide a safer and more comfortable work area.

Benefits of Robotic Storage and Retrieval Systems

Many robotic storage and retrieval systems — including Perfect Pick — are versatile enough to work in most warehouses covering a broad product range. When you choose one of these systems for your operation, you'll experience benefits like:

- Increased efficiency: Systems like Perfect Pick significantly reduce the time and labor involved with manual pick-and-pack applications.

- Improved accuracy: Installing a robotic storage and retrieval system in your facility results in reduced material loss, less product damage and fewer shipping errors. Many systems allow operators to control the iBOT's speed for extra-sensitive applications.

- Energy-efficient: The iBOTs use high-powered ultracapacitors for control and movement that can recapture the energy expended from their continuous operation.

- High scalability: The modular design of these systems offers the flexibility to expand as your production demands increase.

- Fast ROI: Storage and retrieval systems reliably provide a quick return on the initial investment.

- Easily configurable: These systems can seamlessly integrate with most existing WES, WCS and WMS platforms.

Advantages of Choosing Siggins

Siggins has been a leader in providing operations throughout the North America with efficient and affordable material handling solutions since 1946. Since then, we have harnessed modern technology to offer some of the industry's most innovative automated and robotic systems, including Perfect Pick from OPEX. Our professional team is committed to helping you implement the most practical and productive solution to meet your needs.

We'll walk you through the entire process, from consultation and system selection to implementation and post-installation support. We aim to maintain lasting partnerships by giving you the attention and support you deserve.

Contact the Experts at Siggins Today

If you're ready to learn more about how a robotic storage and retrieval system can benefit your operation, the experts at Siggins can help. Connect with us online today to schedule an introductory video consultation.

SPECIFICATIONS

Perfect Pick

- Load weight capacity: 80 lbs (including tote)

- Rack length: Scalable up to 204.9' (62.45 m)

- Rack height: Scalable up to 32.5' (9.90 m)

- Rack width: 9' (2.74 m)

- Tote dimensions: 20" x 30” x 8/10/12/14" H (50.8 cm x 76.2 cm x 20.32/25.4/30.48/35.56 cm H)

- Storage locations: 4,274 (with 12" high totes)

- Cubic feet of storage: 14,573 ft3

- Square feet required: 2,459 ft2

- Tote presentation: Up to 360/hr per workstation

- up to 20 iBOTs?

Perfect Pick HD

- Load weight capacity: 80 lbs (including tote)

- Rack length: Scalable up to 204.9' (62.45 m)

- Rack height: Scalable up to 32.5' (9.90 m)

- Rack width: 14’ (4.27 m)

- Tote dimensions: 20" x 30” x 8/10/12/14" H (50.8 cm x 76.2 cm x 20.32/25.4/30.48/35.56 cm H)

- Storage locations: 8,548 (with 12" high totes)

- Cubic feet of storage: 29,145 ft3

- Square feet required: 2,869 ft2

- Up to 360/hr per workstation

- up to 22 iBOTs